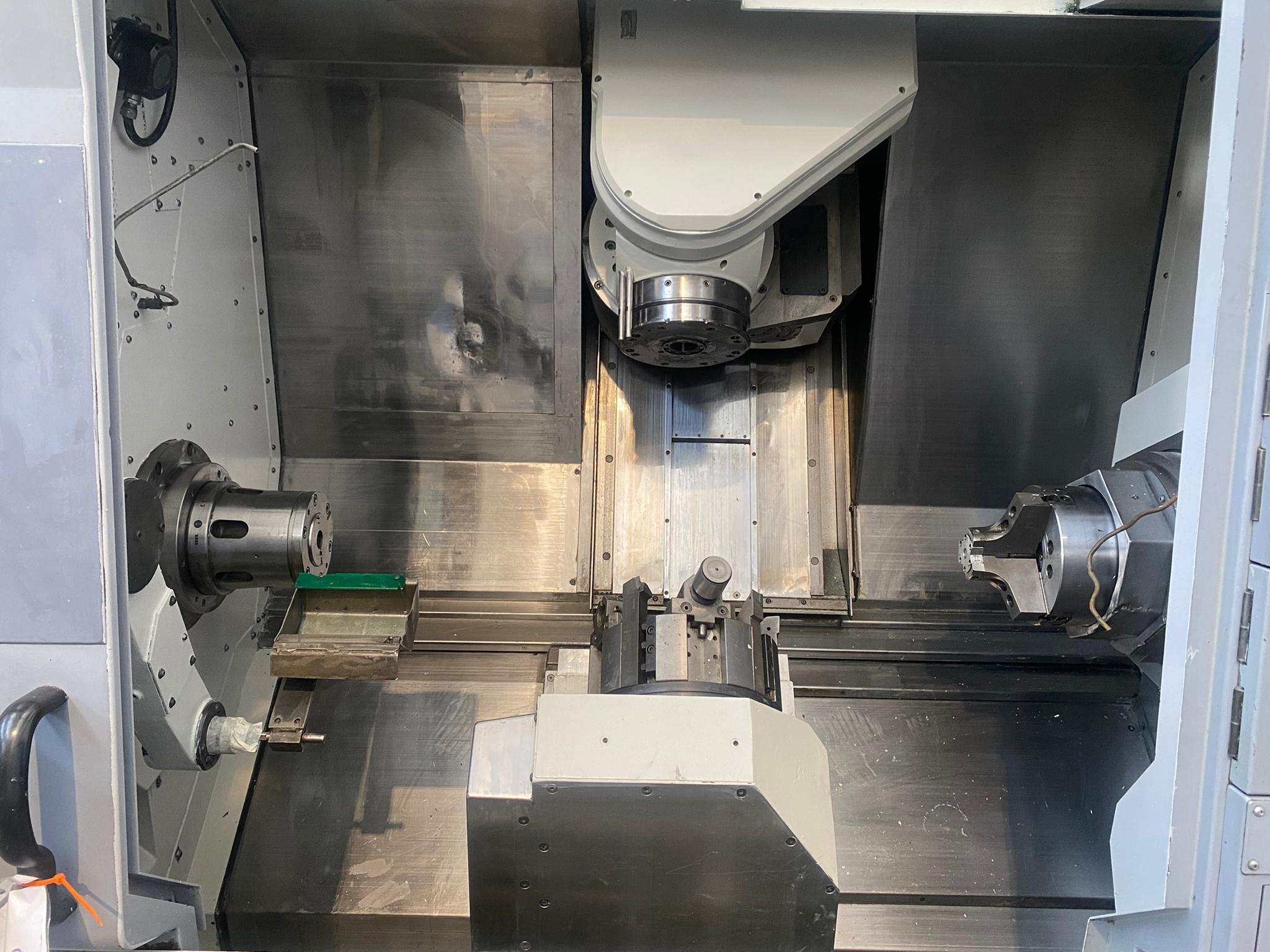

2004 Mazak INTEGREX 200-3ST

2004 Mazak INTEGREX 200-3ST

or

Call +39 0522 1536494

Specifications

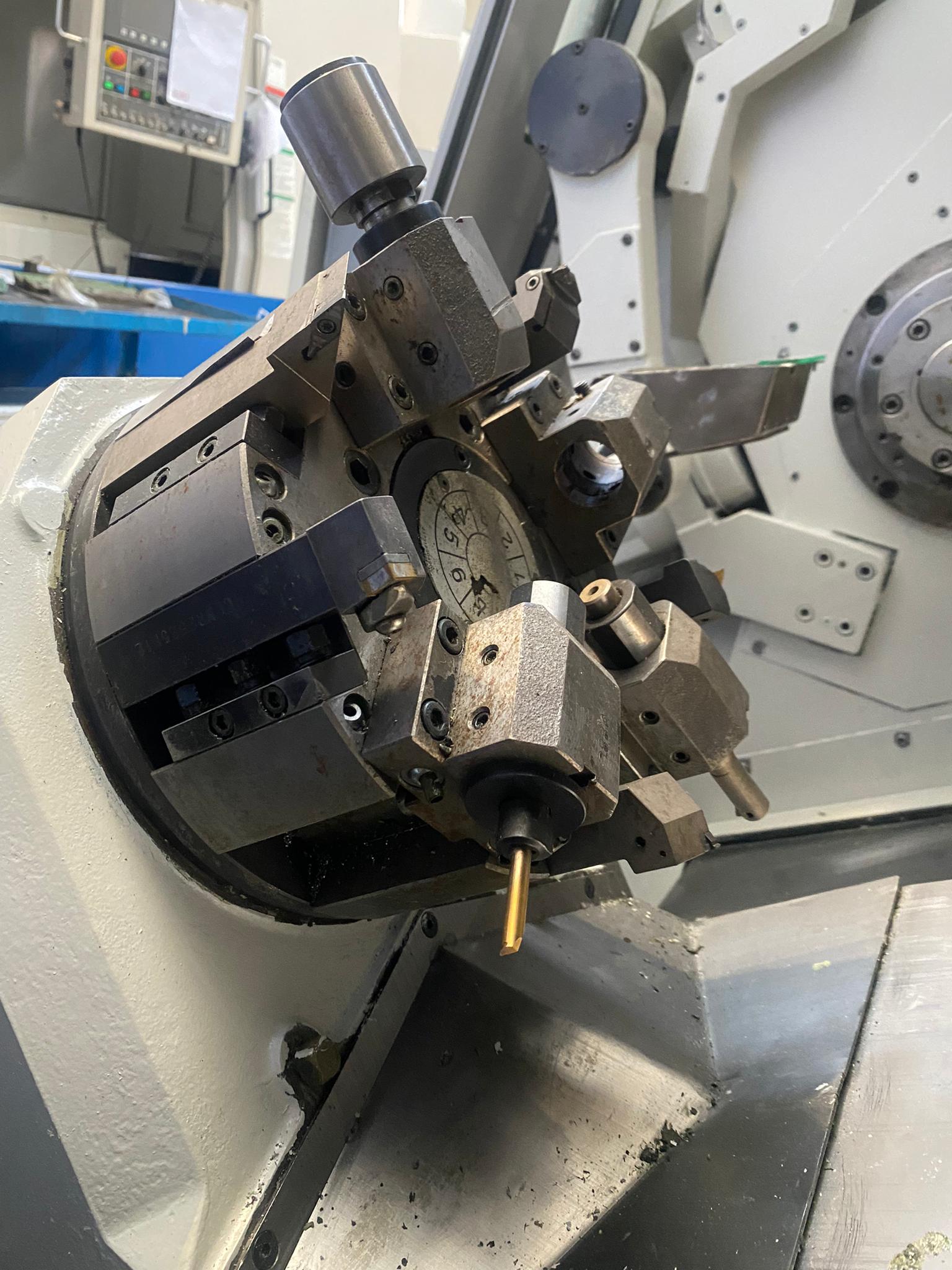

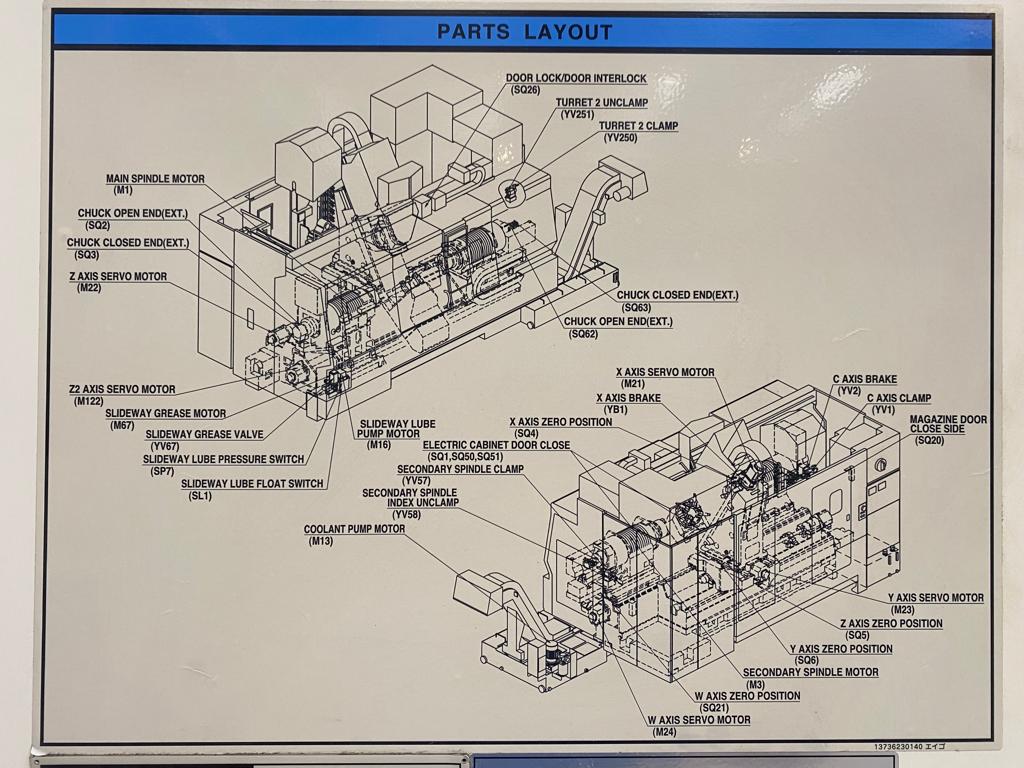

| Manufacturer | Mazak |

| Model | INTEGREX 200-3ST |

| Year | 2004 |

| Condition | Used |

| CNC Control | MAZATROL FUSION 640MT PRO |

| Max swing diameter on bench | Ø 660 mm |

| Max swing over carriage upper turret / lower turret | Ø 660 mm / Ø 500 mm |

| Max turning diameter on upper turret / lower turret | Ø 660 mm / Ø 260 mm |

| Max turning length | 1.016 MM |

| Bar diameter capacity on main spindle / sub-spindle | Ø 65 mm / Ø 65 mm |

| Max piece load capacity on main spindle / sub-spindle | 300 Kg / 300 Kg |

| X1 Axis Travel | 580 mm |

| X2 Axis Travel | 150 mm |

| Z1 Axis Travel | 1.045 mm |

| Z2 Axis Travel | 990 mm |

| Y axis travel | 160 mm |

| W Axis Travel | 1.050 mm |

| C Axis (Main Spindle Rotation / Sub-Spindle) | ±360° / ± 360° |

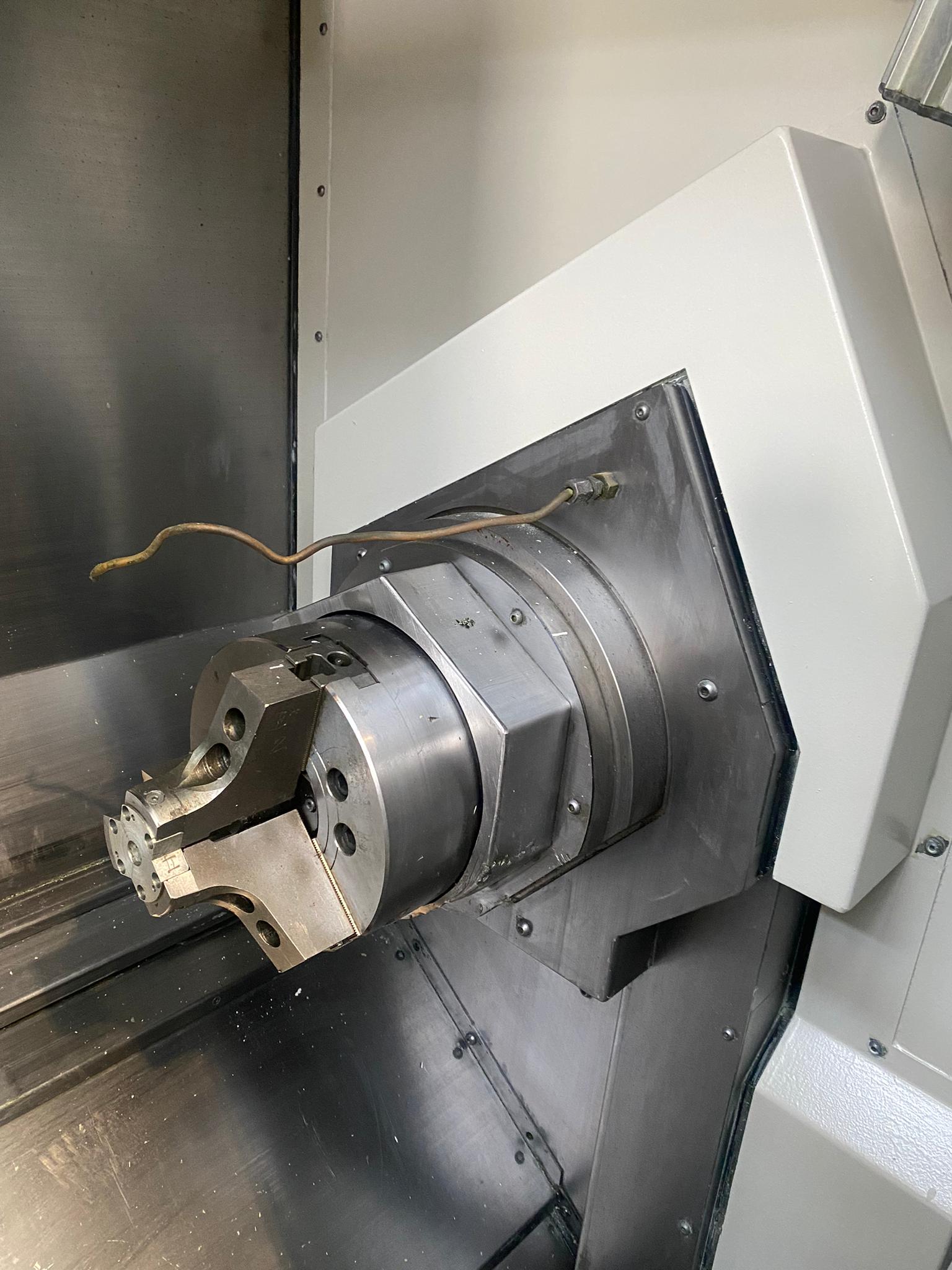

| Main spindle Collet Chuck type | BELLEGRANDI MSCTN70-A6” |

| Main spindle speed | 35 – 5.000 Rpm |

| Main spindle nose | ASA A2-6 |

| Main spindle motor power (cont./30 min.) | 15/22 kW |

| Main spindle C Axis angular positioning of spindle with hydraulic axis locking system | 0.001° |

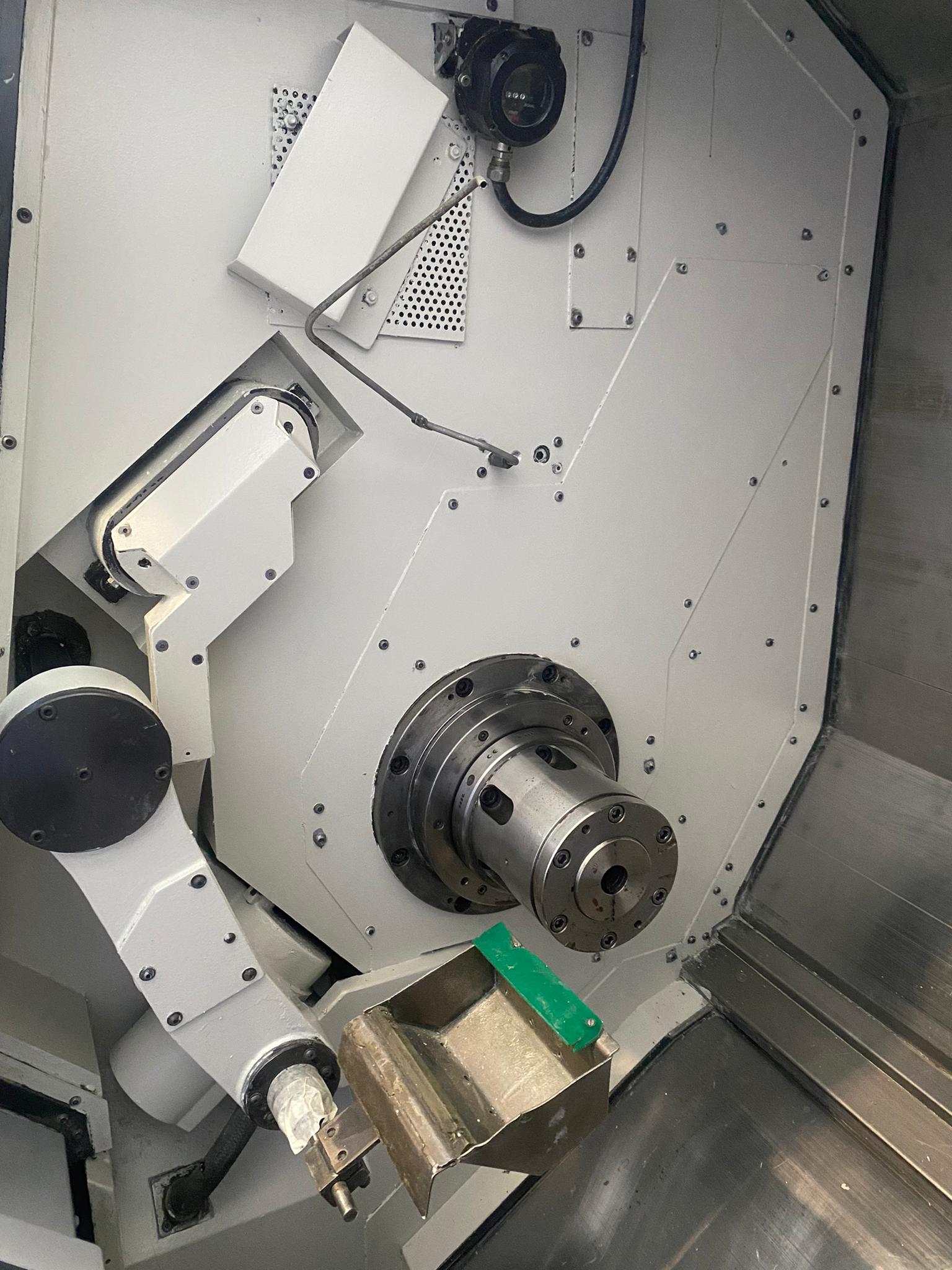

| Sub-spindle chuck diameter | Ø 210 mm |

| Sub-spindle speed range | 35 - 5.000 Rpm |

| Sub-spindle nose | ASA A2-6 |

| Sub-spindle motor power (cont/30 min) | 11/18,5 kW |

| Sub-spindle C Axis angular positioning of sub-spindle with hydraulic axis locking system | 0.001° |

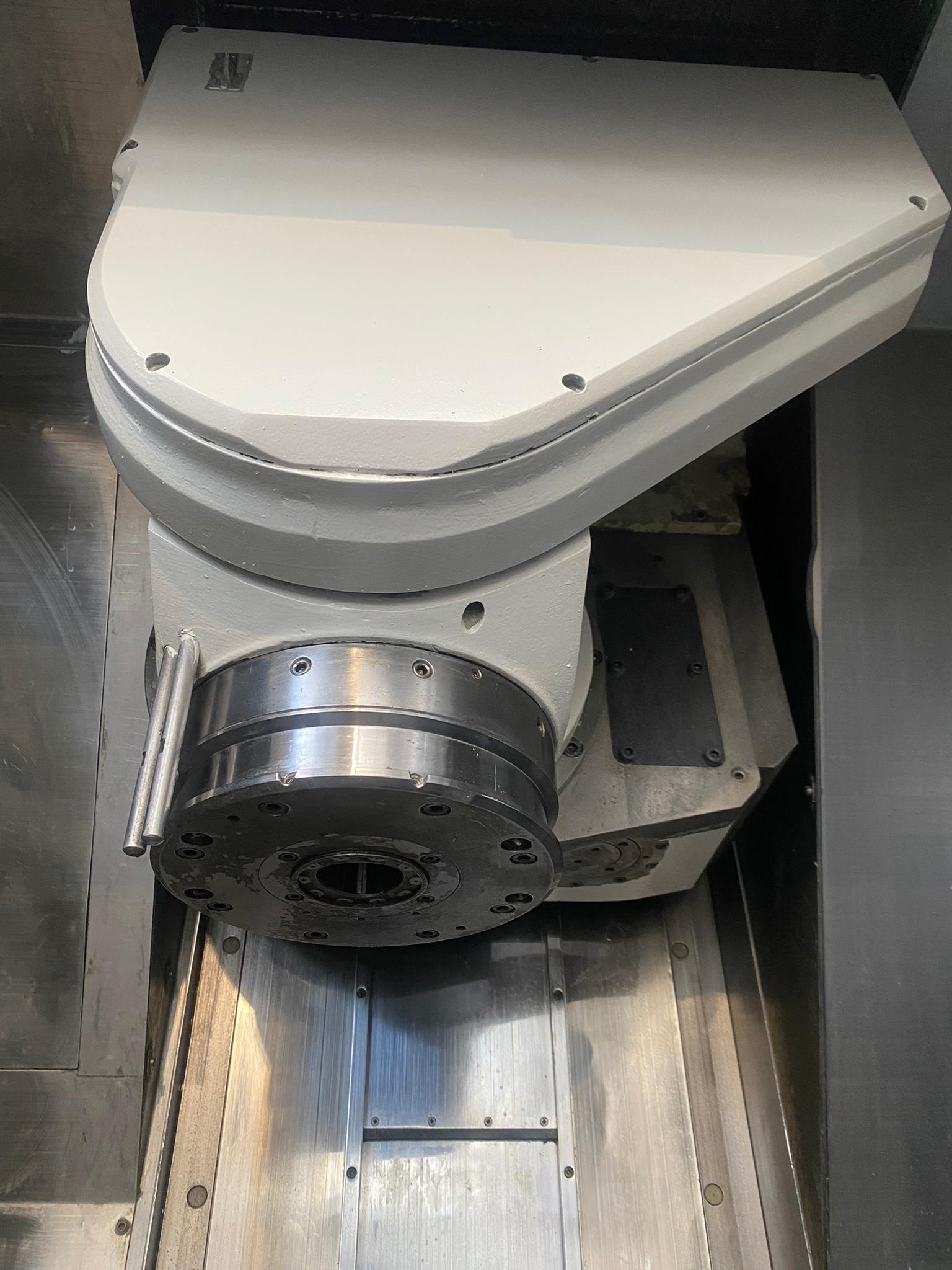

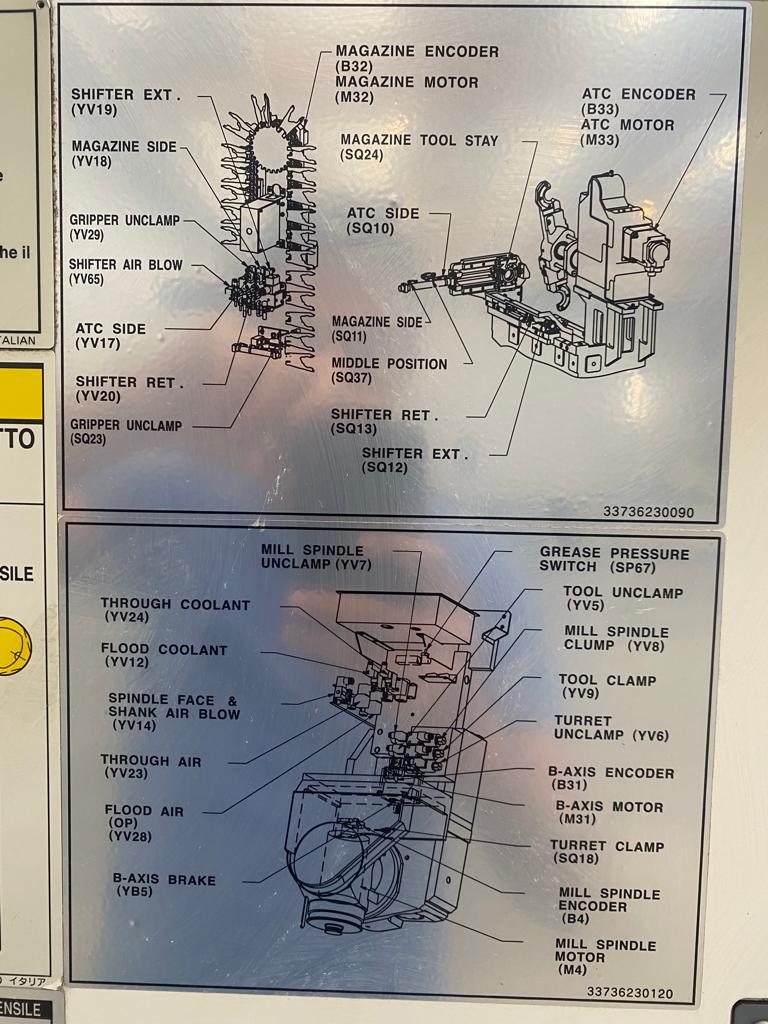

| Milling spindle nose type | CAPTO C6 |

| Milling spindle speed range | 15 - 12.000 Rpm |

| Milling spindle motor power (cont./30 min.) | 5,5 / 15 kW |

| Milling tool magazine capacity | 40 stations |

| Milling tool max diameter | Ø 125 mm |

| Milling tool max length | 300 mm |

| Tool dimensions / boring bar diameter | 25x25 mm / Ø 32 mm |

| Lower turret positions | 9 positions |

| Lower turret tool dimensions / boring diameter | 25x25 mm / Ø 32 mm |

| Rapid feed X1/X2/Z1/Z2 Axes | 38.000 mm/min |

| Rapid feed Y Axis | 26.000 mm/min |

| Rapid feed W Axis | 30.000 mm/min |

| Accessories & Others | Bar feeder make TOP AUTOMAZIONI model XF-365 - Tool presetting automatic descent and ascent (with button and M code) - Chip conveyor - Coolant tank and pumps - Various tool holders - Manuals - Electrical Diagrams - EU/EC Declaration |